Overview

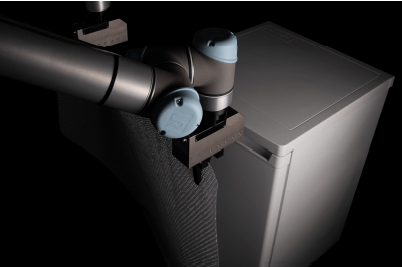

The provided challenge is aiming for a solution to apply air balloon foil to the front door of a refrigerator. Often these doors are made of fragile glass panels and must be specially protected. In order to tape the foil correctly to the door, human skills are required, both in three-dimensional perception and in gripping, because the bubble foil behaves almost unpredictably.

sewts GmbH is a Munich based Advanced Robotics start-up, founded in 2019. With 15 tech enthusiast, they are developing the brain for tomorrow’s robots. By combining Finite Elements Methods (FEM) Computer Simulations with Deep Learning they teach industrial robots a human-like understanding of easily deformable materials, like textiles or foils, to automate even the most complex industrial processes. Their Vision is to fully automate the entire production of clothing.

The processing and production of easily deformable materials, such as textiles or foils, represents a great technical challenge and has barely been automated to date. Textiles and foils have the property of deforming even by slight movements.This makes it difficult to predict their behaviour. Human-like abilities are necessary to understand how to guide foils and textiles safely through an industrial process. For the experiment, a precise physical digital twin of the air balloon foil is created with FEM simulations to obtain training data for the intelligent algorithms. With the help of this data, the robots are taught how to process the foil correctly.

The aim of the experiment is to completely automate the currently manual process step of sticking the air balloon foil onto the door of a refrigerator. The special challenges here are the complex material properties of the film and the variety of refrigerators to be processed. The system must be able to process up to 50 different sizes and shapes. Compared to a human being, who needs 15 seconds for this step, the system can be profitable.